MANUFACTURING PROCEDURE

UNDERBODY COATING What is underbody coating? Underbody coating are those coating which is used to prevent car bodies against rust and corrosion, the underbody coating also helps to protect the car body such as road condition like road rock getting thrown from tires. In others words, underbody coating is a layer which is add on the car body during manufacturing car underbody which protect the car body in winter season from smog or for, and underbody coating is also help to protect the car body in monsoon reason. Underbody coating is very important in India because the road condition is not good and season varies time to time. Underbody coating thickness in India is about 2mm to 3mm it is depend upon the car body and car cost. It is normally sprayed or painted on hen the car is just out of the dealership but if you get your car underbody coating regularly after 3 or 4 year so it will work best. Because the duration of the underbody coating depends on use of the car and area of the drive but is normally good for 3 or 4 year.

Benefit of underbody coating There are many advantages of underbody coating Fight rust –

Underbody coating is very important for Indian market car, it is sufficient for fight with rust and corrosion. Underbody coating is particularly use according to the country and road condition as well as environmental condition if you want to extend your car life to underbody coating is the better option.

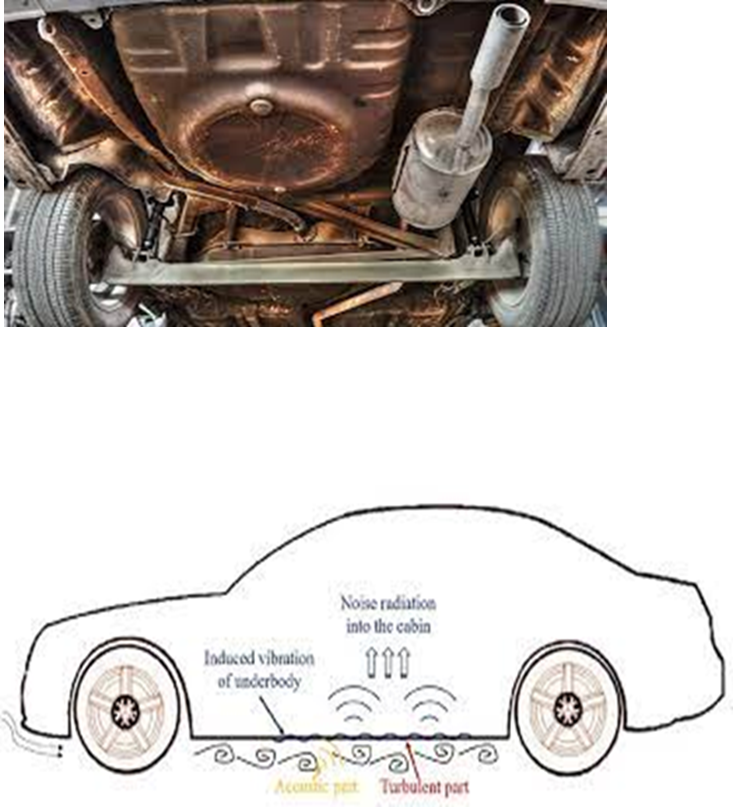

Reduce NVH (noise vibration harshness) level—

Our country if filled with roads patches or the road condition is not good in our country if I talk about the rural area and others so the underbody coating absorb vibration of the and it creates absorb all the unpleasant noise and marginally improve the driving experience.

Prevent paint chipping—

If the car in running on the highway at high speed and or while you are going on the city

road during any metal or a stone of the road bounce from the tire at high speed and momentum and so it can damage of your car body that time underbody coating helps the car body form this type of damages.

Prolong cars life—

A good underbody coating not just protect the car body it also protect the car value if a car

body is not damage or there is no any damages on the body of the car so the values of the car is good and we can easily get good price of the car if there is no any corrosion or rest on the body of the car one time underbody coating extend the values of the car for 4year or more. Underbody coating not just protect the car body it also protects the engine or gear box from corrosion.

Heat insulation—

Temperature of the car increased if the car is parked on the contact of the sunlight through

radiation so underbody work in this case also and maintain the good temperature compare to the atmospheric temperature. Or insulates the interior of the car from the external temperature the vehicle providing a comfortable cabin experience.

Disadvantage of underbody coating: Underbody disadvantage is less comparing to the advantages. Weight of the vehicle – Due to underbody coating the weight of the vehicle will be increase about 10 to 20 ponds because the thickness

of the underbody coating is about 2 to 3mm rubberized so that the fuel consumption will be increases due to which the efficiency or mileage of the vehicle will be decrease.

Cost of the underbody coating –

The cost of the underbody coating is about 2500inr, one time of coating is for only 3 or 4 year it depends on the process of the coating and type of the coating.

TYPR OF UNDERBODY COATING : There are four popular type of underbody body coating 1-Rubberized underbody coating- 2-Polyurethane underbody coating 3-Wax or paraffin base underbody coating 4-Asphalt based underbody coating Rubberized underbody coating—

Rubberized underbody coating is one of the popular coating in the market of underbody or undercarriage, it protects or perveance the underbody well protecting it from scratches it is easily apply undercarriage of the car.

Polyurethane underbody coating—

This coating closes all type of splits and fracture on the underbody of the vehicle when we apply on the car body.It offers good protection against corrosion and also good for bond with the metal you can easily apply another paint on the polyurethane.

Wax-based or paraffin-based underbody coating— A paraffin-based underbody coating is a cheapest option for the underbody coating for protection the car

undercarriage it can easily apply with the help of brush or spray gun. Wax based coating highly adhesive rust protection for treated and untreated undersides. A resistance protection forms once it has dried, which is resistant to weather, road salt and acid. Does not damage plastic, lacquer or rubber.

Asphalt based automotive underbody coating– For standard vehicle, any of the aforementioned type of underbody coating will provide protection for large truck and bus and heavy vehicle or machinery,asphalt based under coating provide extra durability against road rock, ships and moisture. Asphalt based coating is excellent adhesion and will not harden or crack, if you want to get your vehicle coated so no need of painting after asphalt coating. Asphalt based underbody coating does provide some benefits over waxed based underbody coating. They both stick well to most any surfaces and do a great job sealing out moisture.

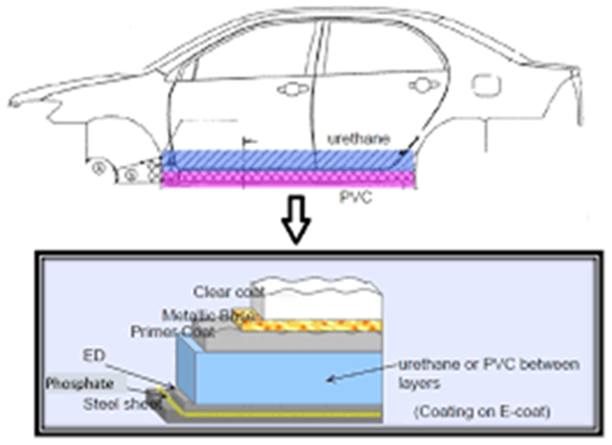

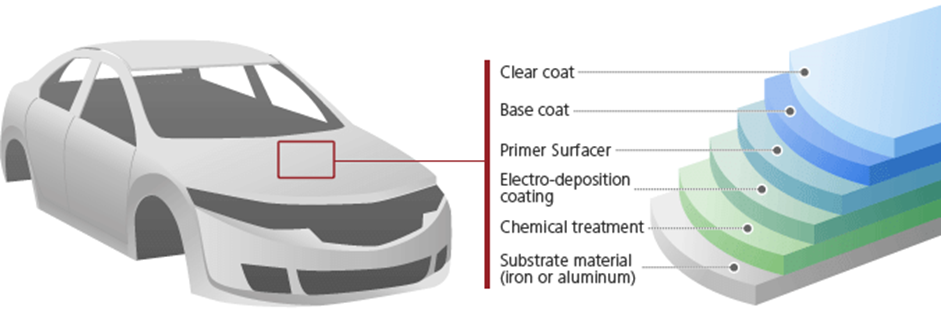

Modern automotive coating process: Modern automotive coating process is complete in the four processes. 1.Pretreatment

2.ED (electrodeposition) coating

3.PVC (poly-vinyl chloride)

4.Primer

5.Topcoats(Base&clear)

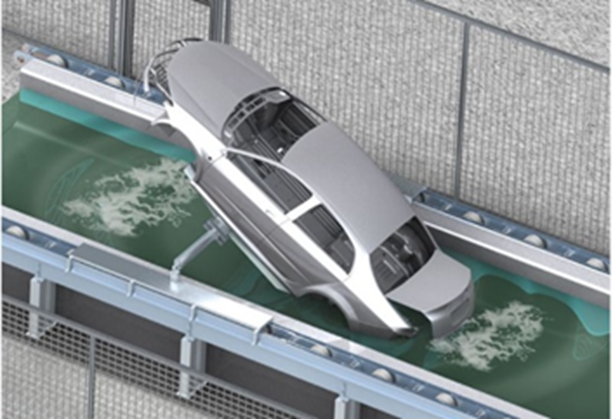

1.Pretreatment – It is the first step for body in white preparation. In pre-treatment consist the cleaning the body surface to remove

remaining oils from steaming process and welding residues through three primary liquid, dip process of degreasing, conditioning and phosphating. The degreasing is the solution is composed of alkaline salts and surfactants and can include caustic soda tri-sodium phosphate and sodium carbonate. The surfactants are type of detergents for emulsifying oils and lubricants.

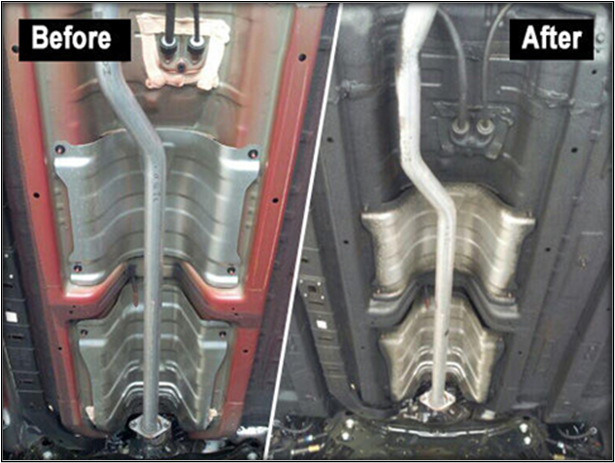

2.Electrodeposition (ED)– the metal underbody coating and frame of automobile are coated to prevent from corrosion or rust, but other

part like roof are not rust proofed the ED process are modified as per the body in white material property. The ED coating provides rust and corrosion protection. After that we apply primer on the material. process- The body is dipped in a tank filled with primer paint. Electric current is passed → paint sticks uniformly. Bake at ~170–180°C to cure the primer.

3.Rust proof material: sealer/ PVC – Poly vinyl of chloride (PVC) it is third step of under body coating and seam sealing using pvc and urethane.

the sealant is applied around and inside the doors, hood, tank and front dash and onto the exterior and interior of the metal joints and outer area of the back wheel well. Sealar applied at- Hemming joints – like doors and tailgate edges. Weld joints – like roof ditch, underbody, rear floor. Seam sealer – for overlapping panels. PVC Underbody Coating – protects from stone chips and corrosion. Foam Application – for NVH (noise, vibration, harshness) control.

4.Primer – It is the fourth step of underbody coating primer can be water-borne, solvent-borne, or a powder between E-coat and top-coat. It provides chipping protection and also improve the finishing of the paint of the car.

5.Base Coar- The Base Coat is the first layer of color paint applied to the car body during the painting process. It is part of the

Top Coat system, which includes: